Date of publication :

July 2012

Key words :

bio-based, bioproduct, biomass, plant ressources, hydraulic fluid, chainsaw, engine, concrete formwork

Despite their undeniable ecological benefits, biolubricants are still struggling to get established compared to synthetic lubricants. But the rise of green chemistry, the regulatory environment and advances in R&D should lead these types of lubricants to develop in the longer term.

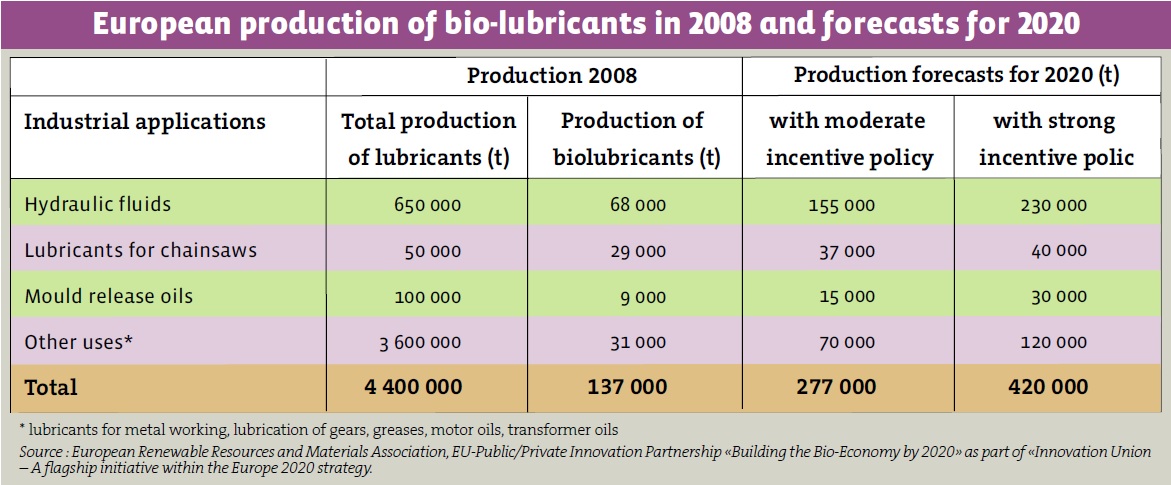

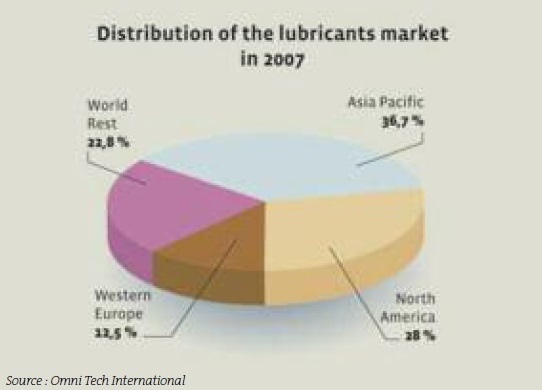

While they were long used as lubricating materials, plant based oils have gradually been overshadowed in the 20th century with the advent of mineral oils derived from oil, which are much cheaper. But with the current rise of plant based chemistry and soaring oil prices, biolubricants are coming back to the fore, notably due to their biodegradability properties and their lower toxic impact. According to research firm Omni Tech International in 2008, the global lubricants market is estimated at 41.8 million tonnes of which Western Europe counts for 12.5% (see graph).

“European production of lubricants is approximately 4.5 million tonnes per year and it is estimated that biolubricants represent about 3% of this production,” says Julie Roïz, head of renewable raw materials projects at ValBiom in Belgium, based on a study by the European Association of renewable materials and resources (ERRMA). She adds: “If you look at the companies currently holding EU eco-labels for lubricants, the leading countries are Germany, France and the Netherlands.”

The biolubricants on the market today come from oilseeds and come in several categories as detailed by Julie Roïz: “The majority of bio-lubricants are based on esters. First, there are natural esters which are triglycerides of vegetable oils. Then we have oleochemical esters of fatty acids such as diesters, polyol esters and complex esters.” These lubricating materials are manufactured from various cultures, usually sunflower or rapeseed, but can also be derived from more exotic oils, as Mathieu Chatillon, head of R&D at Novance explains: “Fatty acids can also come from oil palm and coconut, depending on usage. These oils have different properties compared to those commonly used, especially in terms of oxidation stability, or usage properties when cold.”

Finally, we are seeing the development of new synthetic bases, which were traditionally derived from petrochemicals, but which can now be obtained from non-oil renewable resources “as for example Biofene, by the company Amyris which is obtained from sugar cane” says Julie Roïz (ValBiom).

Biolubricants are used primarily in niche sectors, in applications where recovery is almost impossible or where they likely to be discharged into the environment.

Firstly, biolubricants are used in the lubrication of chain saws. During the use of the tool, oil is subjected to centrifugal force and spread over the forest floor.

Plant based lubricants are also used as hydraulic fluids, to optimise the operation of equipment such as harvesters, cranes, tractors or load carriers in forests.

Biolubricants are also used in greases, particularly for lubricating large sized parts which cannot be continuously covered with oil. This is notably the case for chains used at dams and canal facilities (lock gates).

Engine lubrication is also an area where biolubricants may be of interest. Indeed, motor oils using plant based oils have been developed to better deal with high thermal stresses.

The construction sector also remains an important application for plant based lubricants, especially for concrete moulding.

Finally, they can be used in the field of machining and metal working (cutting oils, cooling parts, corrosion protection, etc.).

And other applications can be considered according to Julie Roïz (ValBiom): “Applications in electrical transformers are an application which might develop.”

Constraints still to be overcome

However, in order to have a chance of competing with petrochemical lubricants, biolubricants must above all become closer in terms of technical performance. “Green chemistry does not necessarily reproduce the advantages brought by petrochemicals,” explains Jean-Louis Pauphillat,

However, in order to have a chance of competing with petrochemical lubricants, biolubricants must above all become closer in terms of technical performance. “Green chemistry does not necessarily reproduce the advantages brought by petrochemicals,” explains Jean-Louis Pauphillat,

president of Molydal, a company specialising in the design, manufacture and packaging of lubricants. He adds: “There are obstacles still to be overcome in terms of the loads and speeds of biolubricants.” Equivalence in terms of technical performance is an essential element, as explained by Mathieu Chatillon (Novance): “Performance is favoured by industry, rather than the sustainable aspect. Environmental impact is significant now, but manufacturers do not want to concede on technical criteria. Lubrication via plant based greases can be better but generally they have less favourable properties when cold.” This type of lubricant also ages less well, according to Cécile Dano, technical development manager at MotulTech specialised in metalworking and industrial lubricants “plant-based lubricants often have a lower oxidation resistance.” However, biolubricants give quite satisfactory performances in certain applications, as explained by Audrey Boutevillain, Ecolabels product manager at the company Condat: “The performances of some biolubricants are already competithere. For some applications, such as hydraulics, they offer even better performance compared to petrochemical- based lubricants.”

Another remaining major obstacle is the cost of these bio-lubricants. “A biolubricant costs somewhere between 30-40 % more compared to a conventional lubricant,” says Jean-Louis Pauphillat (Molydal). But this extra cost is mitigated according to Mathieu Chatillon: “Yes, there is still a slight premium on the price, but we must consider the use of bio-lubricants. They include the ability to reduce energy consumption and engine wear, and therefore costs.” It is an opinion shared by Jacky Vandeputte, project manager at IAR: “To assess the economic benefits of using bio-lubricants, it is important to look at the whole system, by performing a machine cost analysis.”

Furthermore, the question of the availability of cultures comes up, if interest in biolubricants increases. “The difficulty is not merely technical, we also need a way of ensuring the availability of raw materials, and creating a reliable supply chain, which is not easy,” says Cécile Dano (MotulTech), adding: “The problem of the availability of agricultural land should also be considered.” In terms of this issue, Julie Roïz (Valbiom) notes that the use of new resources could be considered: “There is the production of base oils from algae (Solazyme) or cellulosic biomass via a Biomass to Liquid process. But research is still needed in order to develop these technologies and demonstrate their effectiveness.”

To try to overcome the first technological barriers inherent to biolubricants, the European Ibiolab project was launched in 2006 to develop and commercialise innovative and environmentally friendly lubricants and to strengthen the competitiveness of SMEs. “This program bringing together 12 SMEs, as well as 4 associations and 6 research centres, was completed in 2009 and aided in the commercialisation of 10 eco-labelled biolubricants,” says Carine Alfos, director of innovation at Iterg, the coordinator of the projects.

The French institute which is an expert in fatty bodies also participated in the Stanlub project in 2005, which was designed to develop bio-lubricants and green solvents for coatings based on stand oils derived from castor, linseed and tung oils. Currently, Iterg is coordinating the European project Vosolub Eco Innovation, which brings together three companies (RS Clare, Brugarolas, and Motul), technical centres (BfB Oil Research and Techniker), a cooperative (Arterris), an oil producer (Provence oils) and two associations (Valbiom, and Ueil). This program seeks to develop new formulations for bio-lubricants made from sunflowers. “Vosolub is studying the possibilities of direct use of an oil that is rich in oleic fatty acids as a technical solution for lubrication in various applications and processes. By not needing to transform the extracted oils, it reduces the costs associated with this step,” says Carine Alfos. “The Vosolub project uses a particular selection of sunflower oils so that they are rich in oleic acid, making for a non-competithere tive approach to food crops,” adds Cécile Dano (MotulTech).

At Molydal, R&D projects, under the umbrella of the IAR, are currently underway for the development of biolubricants for dam chains, and applications of in metal forming (swaging, cladding).

A favourable regulatory environment

Biolubricants will benefit from the growing interest in environmental issues, but also from the context of current regulations. “Regulation could be an important advantage for biolubricants,” says Mathieu Chatillon (Novance). Since January 1st, the Farming Bill (section 44, Act 2006-11 of the 5th of January 2006) prohibits the use of fossil based lubricants which can easily be substituted with biodegradable products or meet the criteria for the European Ecolabel (see inset) in natural areas classed as “sensitive”. “For now, this regulation does not yet have an implementing decree,” says Virginie Turc, technical director for automotive products at Fuchs France, specialised in the design, manufacture and marketing of lubricants, adding: “Confusion about the term biolubricant is possible, because it can mean that a product may contain at least a large proportion of renewable resources as recommended by the eco-label, or that a lubricant may be petrochemical (from synthetic esters) which is biodegradable.”

In addition to the Farming Bill, the general tax on polluting activities as of January 2008 applies to lubricants which are lost: oils for two stroke engines, greases for open systems, mould release oils, and chainsaw oils. Only products which meet the conditions of the European eco-label are exempt from this tax.

Finally, the REACH regulation should encourage the development of plant -based lubricants, which have more favourable toxicological and ecotoxicological profiles.

The current favourable environment towards biolubricants therefore makes industry players rather optimistic about the viability of a perennial sector. If technical performances continue to improve, then there is no doubting the success of plantbased lubricants. “Biolubricants will win out,” says Jean-Louis Pauphillat (Molydal). It will be a success led primarily via niche markets, as suggested by Audrey Boutevillain (Condat): “The rise of bio-lubricants will essentially be in BtoB in sectors such as aeronautics, public works and forestry management.”

Environmental labels for lubricants

Different types of markings exist to attest to the environmental benefits of lubricants. From 1977, Germany has put into place its Blauer Angel, which guarantees to the consumer the biodegradability and non-toxicity of chainsaw oils, mould releasers and hydraulic fluids. In 2005, the European Commission extended its European Ecolabel which guarantees consumers that products meet the environmental requirements for lubricants. It requires a high percentage of renewable base oils, biodegradability and nontoxicity to the environment. Valid for four years, it concerns lost-use lubricants, such as hydraulic fluids, greases, chainsaw oils, two-stroke engine oils as well as transmission oils, sternpost oils and oils for cables.

Along with these labels, a European project on the display of the environmental lifecycle analysis of biobased products (including lubricants) is currently being validated.

Written by DINHILL ON, Formule Verte

Photos/graphics credits: ERRMA-Building the Bio-Economy by 2020 (picture n°1), Omni Tech International (2), Stihl (3), sxc.hu (4), Molydal (5), Ariane Boixière-Asseray (6)